Unraveling the mystery of where the torque sensor is located is essential for understanding the inner workings of various mechanical systems. Let’s delve into this topic and explore the intricacies of finding the torque sensor in different applications.

1. Understanding the Role of the Torque Sensor

Before locating the torque sensor, it’s crucial to grasp its function. The torque sensor measures the twisting force applied to an object, providing valuable data for monitoring and controlling various systems.

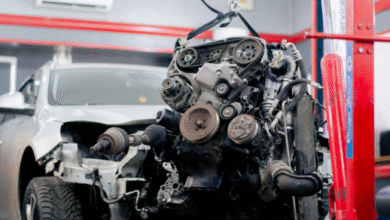

2. In Vehicles: Engine Bay Exploration

In automobiles, the torque sensor plays a pivotal role in the powertrain system. It’s commonly located within the engine bay, typically near the transmission or drivetrain components.

3. Inside the Transmission Housing

Within the transmission housing lies a prime spot for the torque sensor in many vehicles. Its placement in this area allows for accurate measurement of torque output from the engine.

4. Embedded within the Steering Column

In vehicles equipped with electronic power steering systems, the torque sensor is often integrated into the steering column assembly. This location enables precise detection of steering input torque.

5. Aircraft Applications: Engine Monitoring Systems

In aviation, torque sensors are crucial for monitoring engine performance. They are typically situated within the engine assembly, where they measure the torque generated by the aircraft’s engines.

6. Mounted on Rotating Shafts

Torque sensors used in industrial machinery and equipment are often mounted directly on rotating shafts. This placement allows for real-time measurement of torque during operation.

7. Integrated into Load Cells

In manufacturing processes, torque sensors are frequently integrated into load cells. These specialized sensors are installed at key points along assembly lines to monitor torque during production.

8. In Robotics: Joint and Actuator Placement

In robotic systems, torque sensors are strategically placed at joints and actuators. This positioning enables robots to precisely control torque output and interact safely with their surroundings.

9. Subsea Installations: Underwater Monitoring

For underwater applications such as offshore drilling rigs, torque sensors are installed within subsea equipment. These sensors withstand harsh underwater conditions while providing vital torque data.

10. Integrated into Dynamometers

Dynamometers, used for measuring engine performance, incorporate torque sensors into their design. These sensors accurately gauge the torque output of engines under various operating conditions.

11. On Bicycle Cranksets

In the realm of cycling, torque sensors are often found on bicycle cranksets. These sensors measure the force applied to the pedals, providing valuable feedback for cyclists and performance analysis.

12. Mounted on Industrial Tools

Torque sensors play a critical role in industrial tools such as torque wrenches and screwdrivers. These sensors are typically integrated into the tool’s design to ensure accurate torque application.

13. In Wind Turbine Nacelles

Within wind turbine nacelles, torque sensors are vital for monitoring the performance of the turbine’s drivetrain. These sensors help optimize energy production and detect potential mechanical issues.

14. Positioned in Hydraulic Systems

In hydraulic systems, torque sensors may be positioned along hydraulic lines or within hydraulic cylinders. These sensors measure torque within the system to ensure proper operation and safety.

15. Within Electric Motor Assemblies

In electric motors, torque sensors are often integrated directly into the motor assembly. This placement allows for precise control of torque output in various applications.

16. Embedded in Medical Devices

Torque sensors are utilized in medical devices for applications such as robotic surgery and prosthetics. These sensors are carefully integrated into device designs to ensure accurate torque measurement.

17. In Marine Propulsion Systems

Torque sensors are integral components of marine propulsion systems, including boat engines and thrusters. They are typically located within the propulsion unit to monitor torque output during operation.

18. Positioned in Aerospace Control Systems

In aerospace applications, torque sensors play a crucial role in flight control systems. They are strategically positioned within control surfaces to measure torque and ensure stable flight operations.

19. Within Test and Measurement Equipment

Torque sensors are essential components of test and measurement equipment used in research and development settings. They are often integrated into testing apparatus to measure torque accurately.

20. In Earthmoving Machinery

Torque sensors are utilized in earthmoving machinery such as excavators and bulldozers. These sensors help monitor torque output during heavy-duty operations, ensuring efficient performance.

21. Integrated into Prosthetic Limbs

In the field of prosthetics, torque sensors are incorporated into artificial limbs to provide users with natural movement and control. These sensors enable precise torque adjustment for optimal functionality.

22. Within Agricultural Machinery

Torque sensors find application in agricultural machinery for tasks such as tractor operation and equipment calibration. They are positioned within critical components to ensure reliable performance.

23. Embedded in Elevator Systems

Elevator systems rely on torque sensors to monitor motor performance and ensure smooth operation. These sensors are often integrated into the motor assembly or control system for precise torque measurement.

24. Within Industrial Robots

In industrial automation, torque sensors are essential for robotic applications such as assembly and material handling. These sensors are strategically positioned within robot arms for accurate torque control.

25. Embedded in Power Generation Equipment

Torque sensors play a vital role in power generation equipment such as generators and turbines. They are located within key components to monitor torque output and optimize energy production.